Introduction

In the contemporary industrial age, the combination of technology with conventional manufacturing methods has brought forth a new era of operational effectiveness and creativity. At the heart of this revolution is Manufacturing Analytics, a crucial technology that uses Data Analytics to change the manufacturing landscape. This method not only improves production efficiency but also leads to breakthroughs in Predictive Maintenance, Supply Chain Optimization, and Quality Control Analytics, among other areas.

As industries move towards the Industry 4.0 concept, which includes the use of Industrial IoT and Smart Factory technologies, the importance of Manufacturing Analytics in promoting Data-Driven Manufacturing becomes more and more crucial. The incorporation of Machine Learning in Manufacturing and Real-Time Monitoring systems demonstrates how Operational Efficiency and Production Performance Metrics are being redefined through data.

However, in the middle of these technological advancements, a difficult question arises: How can manufacturers effectively handle the complexities of excessive data to gain useful insights?

The solution can be found by strategically using Manufacturing Analytics. Through the use of sophisticated Data Analytics and digital transformation in the manufacturing industry, organizations may examine large amounts of data, recognize trends, and make well-informed choices that enhance the optimization of manufacturing processes and enable proactive analysis of equipment failures.

Understanding Manufacturing Analytics

Utilizing Data Analytics to transform the industrial sector’s manufacturing processes’ management, optimization, and execution forms the foundation of integrating Manufacturing Analytics. Thanks to this critical integration, which signifies a significant change in manufacturing paradigms, businesses may now attain previously unheard-of levels of production efficiency, quality control, and operational efficiency.

Manufacturing Analytics enables businesses to analyze large, complex data sets, spot trends, predict future ones, and make snap choices by leveraging massive amounts of data from Industrial IoT devices, Real-Time Monitoring Systems, and manufacturing operations. This guarantees that manufacturing lines are effective and flexible by streamlining operating procedures, cutting waste, and improving response to market changes.

Thanks to the application of Manufacturing Analytics, which goes beyond simple process optimization to drive innovation in product creation and operational strategy, data is now firmly entrenched as the cornerstone of modern manufacturing excellence. Thanks to this ground-breaking method, manufacturers can achieve productivity and quality levels that were previously thought to be impossible, underscoring the critical role that Data Analytics will play in influencing industrial operations going forward.

Here’s a summary of how Data Analytics-driven Manufacturing Analytics is reshaping the manufacturing sector, along with some important numerical insights:

1. Production Efficiency:

Up to 20% more production efficiency can be achieved by manufacturers by analyzing real-time data from Industrial IoT devices. Process simplification and inefficiency identification are used to accomplish this.

2. Predictive Maintenance:

Up to 20% more production efficiency can be achieved by manufacturers by analyzing real-time data from Industrial IoT devices. Process simplification and inefficiency identification are used to accomplish this.

3. Supply Chain Optimization:

Manufacturing Analytics increases visibility and agility, which enables Supply Chain Optimization. When businesses include analytics in their supply chain operations, they may see a 10–20% decrease in operational expenses and a 10–30% improvement in delivery performance.

4. Quality Control Analytics:

With the use of advanced Data Analytics, manufacturers may greatly improve the quality of their products by finding and repairing defects early in the production cycle. By taking a proactive stance, the manufacturing process is accelerated and the tightest quality standards are met before items are released onto the market.

Consequently, expenses related to quality-related problems might potentially drop by 15%, indicating the observable economic advantages of incorporating sophisticated analytics into manufacturing tactics.

5. Data-Driven Manufacturing:

By utilizing Smart Factory Technologies, Data-Driven production has increased production output by 12% and decreased maintenance expenses by 30%.

6. Real-Time Monitoring Systems:

By providing data for continual development, Real-Time Monitoring System deployment enhances operational efficiency and enables prompt solutions to production difficulties. It has been demonstrated that this can boost efficiency by up to 25%.

7. Operational Efficiency Metrics:

Businesses have witnessed a 5–10% reduction in energy use by utilizing Manufacturing Analytics’ Operational Efficiency Metrics, demonstrating effective production techniques’ economic and ecological advantages.

Learning Manufacturing Analytics is about radically changing the way manufacturing activities are carried out, not merely about implementing new technologies. It necessitates a culture that values continuous improvement, a deliberate approach to data management, and qualified staff to interpret Data Analytics.

The metrics, which emphasize the potential for cost reductions, efficiency gains, and quality improvements, amply demonstrate the substantial advantages of incorporating Data Analytics into manufacturing operations. Manufacturing Analytics will play an ever more important role in the industry as it develops, spurring innovation and global competitiveness.

The Benefits of Manufacturing Analytics

Finding Manufacturing Analytics’ many benefits is like unwrapping a treasure trove for today’s firms. There’s more to finding those pearls of wisdom that can radically change industrial processes than just crunching numbers and getting lost in Data Analytics.

To begin with, picture yourself being able to increase your manufacturing efficiency by up to 20%. That is the reality for businesses that use the data from the many sensors and gadgets scattered throughout their operations. Working harder alone won’t cut it; you also need to work smarter, identifying the small hiccups along the way that, when fixed, will turn the whole thing into a well-oiled machine.

And there’s the quality control magic wand. Manufacturing Analytics gives you the ability to identify flaws before they become expensive errors, much like having a sixth sense. In addition to keeping your customers satisfied, this proactive approach can reduce quality-related expenditures by up to 15%. Ensuring sure only the greatest products leave your doors is akin to having an extremely keen eye for detail.

Costs, the specter that hovers over every firm can also be drastically reduced. Imagine increasing your delivery performance by 10–30% while reducing your operational costs by 10–20%. This is the kind of efficiency that Manufacturing Analytics provides, simplifying and cutting the intricate network of supply chain activities into an economical procedure.

Additionally, we must not overlook your equipment, the unsung hero of manufacturing. With the help of Data Analytics, predictive maintenance can be compared to having a crystal ball that can predict precisely when and where a machine will break. By using planned downtimes to address issues early on, you may save maintenance expenses by up to 30% and maintain a smooth production line.

However, confidently navigating the ship is more important than simply keeping the gears turning in Manufacturing Analytics. Assuring that every decision, from product design to market strategy, is supported by reliable data, it provides decision-makers with the information they need to negotiate the intricacies of the industrial environment.

Manufacturing Analytics continues to be a shining star in the fight for sustainability. It not only helps decrease costs by 5–10% but also opens the door for greener production methods by revealing places where energy consumption can be lowered. It’s about maximizing environmental sustainability by achieving more with less.

Perhaps the most exciting aspect is the capacity to innovate and react quickly to changes in the market. Businesses can remain ahead of market demands and technology changes by incorporating Manufacturing Analytics into their product development and operational plans.

Fundamentally, Manufacturing Analytics is a revolutionary methodology that reimagines what is feasible in the manufacturing industry rather than only a technology. It’s about converting obstacles into chances and information into judgments. The road to operational excellence and leadership in the industry is open to those who are prepared to take it.

Implementing Manufacturing Analytics

Manufacturing companies may use Manufacturing Analytics to optimize their operations, enhance the quality of their products, and inform strategic decision-making. It’s a transformative process. This procedure comprises several crucial actions and factors that guarantee the effective adoption and application of analytics in manufacturing settings.

Here’s a deeper look into the process of implementing Manufacturing Analytics:

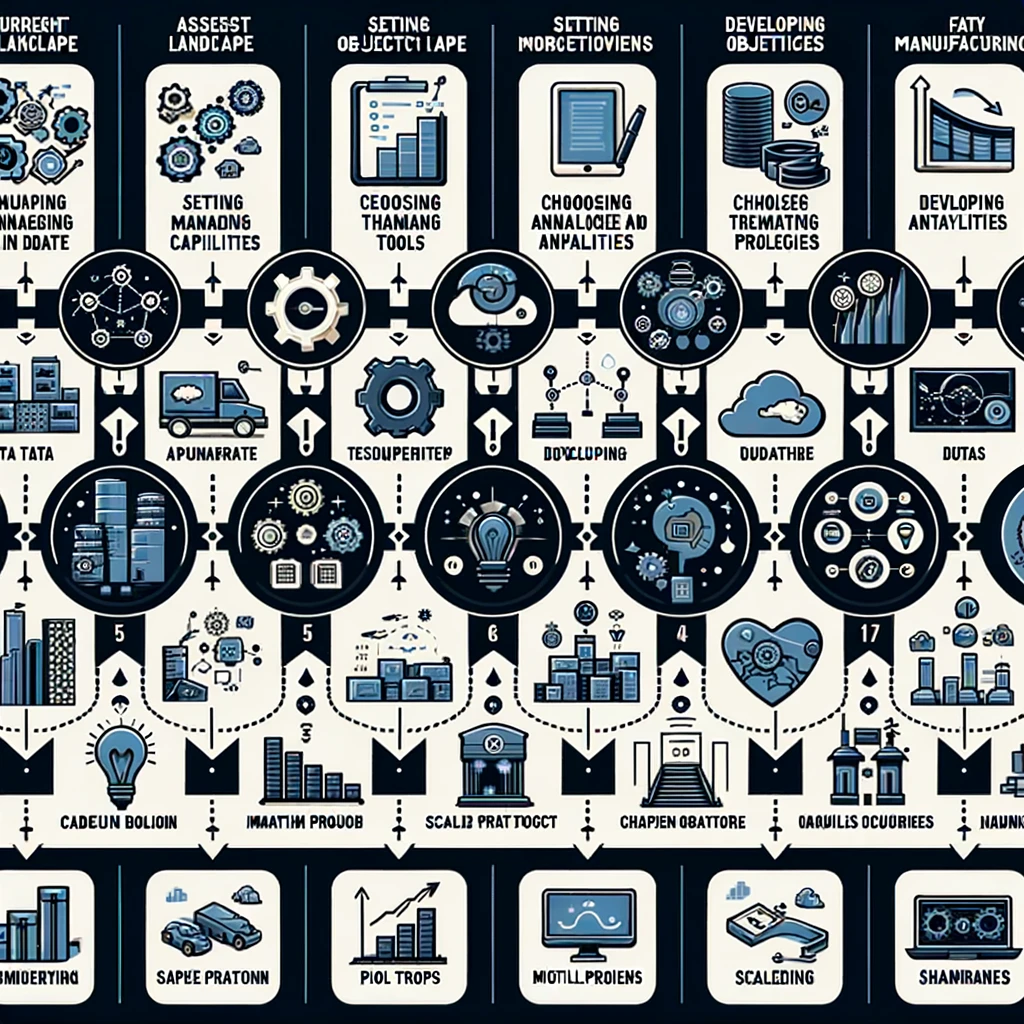

1. Assessing the Current Landscape

The first step is to extensively evaluate the current manufacturing procedures, IT setup, and data capacities. It’s critical to know where your business stands about data gathering, storage, and analysis. This evaluation aids in locating data infrastructure weaknesses and places where Manufacturing Analytics may make quick changes.

2. Setting Clear Objectives

Establish attainable goals for the things you hope to achieve with Manufacturing Analytics. Setting clear objectives will assist direct the implementation process and gauge performance, whether the objective is to optimize the supply chain, improve quality control, decrease downtime, or increase production efficiency.

3. Data Integration and Management

It is crucial to integrate data from multiple sources, including ERP systems, Real-Time Monitoring Systems, and Industrial Internet of Things devices. By ensuring that data is gathered centrally, this step makes analysis simpler. To preserve the accuracy and integrity of data, effective data management procedures must be implemented.

4. Choosing the Right Tools and Technologies

Choosing the right technologies and tools for Data Analytics is essential. The solutions you select should be in line with the goals of your business, your IT setup, and the personnel’s skill levels. It could entail off-the-shelf software with features for process optimization, performance monitoring, and predictive maintenance, or it could involve custom analytics solutions.

5. Building Analytics Capabilities

Creating or obtaining the required analytics skills is a critical step in the implementation process. This could entail collaborating with outside experts, recruiting fresh people with experience in Data Analytics, or educating current employees. Effective data analysis and the extraction of useful insights depend on assembling a team with the appropriate competencies.

6. Pilot Projects

Before a full-scale rollout, you can evaluate Manufacturing Analytics in restricted situations by beginning with pilot projects. It offers a chance to recognize possible obstacles, evaluate the efficacy of analytics solutions, and show stakeholders early successes.

7. Scaling and Continuous Improvement

Scaling Manufacturing Analytics to other manufacturing domains is the next step after successful pilot programs. Increasing the use of analytics, including new data sources, and continuously improving analytical models are all part of this phase. It’s a process of ongoing improvement where discoveries prompt additional optimizations.

8. Cultivating a Data-Driven Culture

Last but not least, the firm must foster a data-driven culture for Manufacturing Analytics to be genuinely effective. This entails promoting teamwork, creating a climate that values decisions based on data, and making sure that analytics-derived insights are put into practice.

Putting new technology into practice is only one aspect of implementing Manufacturing Analytics; another is deliberately changing processes to become more data-informed. In an industry that is always changing, this trip can greatly improve operational efficiency, product quality, and market response for firms.

Conclusion

In summarizing the findings of production Analytics, it is evident that this technology represents a fundamental shift in the production paradigm rather than merely a fad. Manufacturers may make data-driven decisions that improve production efficiency, quality control, and operational efficiency by strategically implementing Data Analytics. The process of integrating Manufacturing Analytics requires a comprehensive strategy that starts with an evaluation of the company’s current procedures and data capabilities, is followed by the establishment of specific goals, and a careful selection of the appropriate tools and technologies that support those objectives.

The process of implementation serves as more evidence of how crucial it is to develop or improve a team’s analytical abilities, beginning with pilot projects to test and learn before progressively scaling up to alter the manufacturing operation as a whole. The most important thing, maybe, is to make sure that the company has a data-driven culture so that Manufacturing Analytics insights are efficiently converted into strategy.

Manufacturing Analytics stands out as a light of innovation, providing a route to not only survive but prosper in this new era, as the manufacturing industry continues to change in response to technological breakthroughs and altering market demands. Through the transformation of obstacles into opportunities and the utilization of data to guide all facets of the manufacturing process, businesses can achieve previously unattainable standards of productivity, excellence, and marketability.

A potent instrument that is redefining manufacturing possibilities is manufacturing analytics. It approaches a thorough plan for improving every phase of the production process, from the manufacturing floor to the customer’s door. Producers who are prepared to take on this revolutionary journey will reap substantial benefits, laying the groundwork for a time in the future when production methods will become more intelligent, efficient, and natural due to data-driven insights. We are just now starting to see how this is changing the industry, but this is not just the manufacturing of the future—this is the manufacturing of the present as well.

As the manufacturing industry prepares to enter this revolutionary era, the journey toward Data Analytics and its numerous applications across industries is far from complete. Visit quickattain.com if you’re ready to learn more about how data analytics is influencing our world today, from business intelligence to cutting-edge discoveries across a range of industries. Discover a multitude of articles and resources aimed at providing you with the understanding and awareness required to successfully traverse the technological and industrial future.